Facts about the Aerial Application Industry

- There are approximately 1,560 aerial application businesses in the United States.

- There are approximately 3,400 total ag pilots in the U.S., including roughly 2,000 hired pilots and 1,400 owner/operator pilots. (Approximately 87 percent of aerial application business owners in the U.S. are also agricultural pilots.)

- NAAA represents more than 1,800 members.

- According to NAAA records, aerial application operations are located in 45 states—all but Connecticut, Hawaii, Rhode Island, Vermont, and West Virginia.

- Aerial applications are conducted in all 50 states.

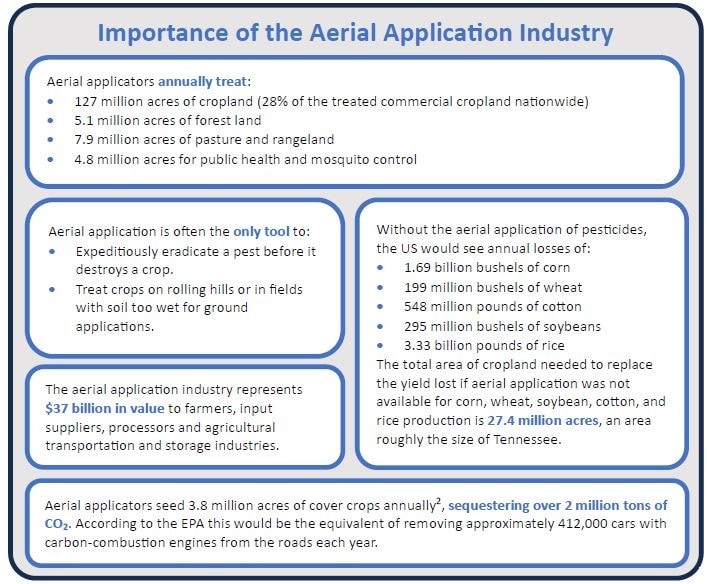

- Based on a 2019 NAAA survey, the agricultural aviation industry treats 127 million acres of cropland aerially each year.

- According to the 2017 USDA Census of Agriculture there are 347 million acres of cropland used for crop production in the United States. Taking into account some crops are treated more than once during a season, aerial application treats an estimated 28 percent of this cropland.

- Nearly 100 percent of forest protection applications are made by the agricultural aviation industry.

- In addition to agricultural aviation, the industry provides firefighting and public health application services to combat disease-carrying mosquitoes.

- Based on a 2019 NAAA survey, the five most commonly treated crops among aerial application operators are corn, wheat/barley, soybeans, pastures/rangelands and alfalfa, but aerial applications are used on nearly all crops.

- Aerial application is often the only, or most economic, method for timely pesticide application. It permits large and often remote areas to be treated rapidly, far faster than any other form of application.

- When wet soil conditions, rolling terrain or dense plant foliage prevent other methods of treating an area, aerial application may be the only remaining method of pest treatment.

- Aerial application is conducive to higher crop yields, as it is non-disruptive to the crop by treating above it and not within it. A study by a crop protection product manufacturer of applications on corn showed aerial application increased yield 8 percent more than ground application.

- Aerial application does not cause soil compaction, hence preventing soil runoff.

- The aerial application of crop protection products results in greater harvest yields of crops. This in turn results in less land being used for agricultural production, preserving important wetland and forest ecosystems important to carbon sequestration and habitat to threatened and endangered species.

- On average, each aerial application business has 2.3 aircraft, ranging in price from $100,000 to nearly $2 million depending on hopper size, engine type and engine size.

- 84 percent of the aircraft used are fixed-wing; the remaining 16 percent are rotorcraft/ helicopters.

- Of the combined fleet, 81 percent are turbine powered and 19 percent have piston engines.

- Ag aircraft are ruggedly built to handle 30 to 100 takeoffs and landings every day from rough landing strips, and they offer protection and good visibility for the pilot.

- Today’s aircraft utilize sophisticated precision application equipment such as GPS (Global Positioning Systems), GIS (geographical information systems), flow controls, real time meteorological systems and precisely calibrated spray equipment.

- Precision application equipment results in less pesticide product being applied to more acres and can ensure an even more targeted delivery by further mitigating off-target drift. The ability to precisely apply products also results in greater fuel efficiency.

- On average, each aerial application business has 2.3 aircraft, ranging in price from $100,000 to nearly $2 million depending on hopper size, engine type and engine size.

- 84 percent of the aircraft used are fixed-wing; the remaining 16 percent are rotorcraft/ helicopters.

- Of the combined fleet, 81 percent are turbine powered and 19 percent have piston engines.

- Ag aircraft are ruggedly built to handle 30 to 100 takeoffs and landings every day from rough landing strips, and they offer protection and good visibility for the pilot.

- Today’s aircraft utilize sophisticated precision application equipment such as GPS (Global Positioning Systems), GIS (geographical information systems), flow controls, real time meteorological systems and precisely calibrated spray equipment.

- Precision application equipment results in less pesticide product being applied to more acres and can ensure an even more targeted delivery by further mitigating off-target drift. The ability to precisely apply products also results in greater fuel efficiency.

- The average hired aerial applicator pilot has 19.4 years of experience in the industry, whereas the average aerial applicator operator has 27.9 years of experience.

- Ag pilots have their commercial pilots’ licenses. They also must be registered as commercial pesticide applicators in the states in which they make applications and must meet the requirements of Federal Aviation Regulations Part 137 which allows for low-level aviation operations.

- NAAA developed the Professional Aerial Applicators’ Support System (PAASS) to provide pilots continuing education about safety, security and drift mitigation. PAASS is attended annually by nearly 2,000 pilots and operators and has resulted in markedly improved safety and environmental stewardship statistics.

- NAAA’s Operation S.A.F.E. (Self-regulating Application & Flight Efficiency) program enables aerial applicators to attend fly-in clinics and have their aircraft professionally analyzed for spray pattern uniformity and droplet size.

- NAAA works with the federal government to invest in researching, developing and testing aerial application technologies to strengthen the safe application of crop protection products by air.

- Obstacles– From 2009 to 2018, 9 percent of aerial application fatalities were the result of collisions with towers, while collisions with power lines account for an additional 13 percent of the accidents and 12 percent of the reported fatalities in the industry. NAAA is urging the FAA to provide improved guidance on marking obstacles, including expanding tower marking guidance to include all guy wire and free-standing towers more than 50 feet in height.

- Funding– Federal funding for aerial application research must be maintained, as it improves the precision and efficacy of aerial application. In addition, USDA economists have found that every dollar invested in agricultural research has a $20 return to the American economy.

- NPDES Permits– NAAA is lobbying Congress to exempt duplicative, unnecessary and burdensome NPDES pesticide general permits for pesticide applications. The Federal Insecticide, Fungicide & Rodenticide Act requires the safety of pesticides to water before they may be registered for use.

- Taxes and User Fees – The current exemption for agricultural aviation from federal aviation fuel excise taxes must be maintained for ag aviators and they must be exempt from user fees. The majority of agricultural aviation operators do not use public airports; rather they use their own private landing strips and rarely, if ever, use or show up on the nation’s air traffic control system network because they are restricted category aircraft that fly at low altitudes in uncongested airspace.

- Taxes and User Fees – The current exemption for agricultural aviation from federal aviation fuel excise taxes must be maintained for ag aviators and they must be exempt from user fees. The majority of agricultural aviation operators do not use public airports; rather they use their own private landing strips and rarely, if ever, use or show up on the nation’s air traffic control system network because they are restricted category aircraft that fly at low altitudes in uncongested airspace.

Environmental Benefits

One of the most promising conservation practices aerial applicators can assist farmers with is cover crops. Cover crops are grasses, legumes, small grains and other low-maintenance crops planted specifically to improve soil health and biodiversity. By sowing the seeds aerially with a preharvest cover crop application, cover crops control erosion, retain and recycle soil nutrients, build organic matter to improve soil health, improve water quality and moisture availability, and break disease and insect cycles.

Soil and Water Quality

Quick growing cover crops hold soil in place, protecting against erosion from wind, rainfall and snowmelt. By slowing erosion and run-off, this in turn helps protect water quality by reducing sediment in streams, rivers and lakes.

Soil health is improved as decomposing cover crops add natural nutrient compounds to the ground, including nitrogen. Subsequently, this reduces the need for future nitrogen fertilizer applications, lowering the production cost of cash crops and reducing fertilizer runoff. Reducing the need for fertilizer makes cover crops ideal for improving soil health over a large area. Aeri applicators are uniquely qualified to help farmers seed cover crops in this regard, due to the speed and precise timing of aerial application and longer timeframe an aerially applied cover crop has to grow, aerate and contribute natural nutrients and moisture to the soil.

While there are several methods of seeding cover crops, aerial application is the most effective means of applying cover crops successfully. The best time to apply many cover crops is when the harvestable cash crop is still standing. Aerial application offers the ability to spread the cover crop seed over the existing crop without any disruption to the standing crop. This means the cover crop can already be established when the cash crop is harvested. Using a drill to plant cover crops requires a terrestrial vehicle and for the grower to wait until their cash crop is out of the field, which might not be the best timing for establishing a healthy cover crop. This can be especially true in northern parts of the U.S. where the first frost can interfere with cover crop growth if they are seeded too late. Aerial application can also be used when the soil is wet and can seed many acres quickly. As timing is a critical part of successfully establishing a healthy cover crop, it is clear that aerial application offers benefits over all other methods of seeding cover crops.

The roots of cover crops increase water-holding capacity, reducing susceptibility to drought. Leaves of cover crops provide shading, which can help control the rate of evaporation from the soil. Per the Plant and Soil Sciences eLibraryPro, under a well-developed crop canopy “the initial evaporation rate for a wet soil surface will be lower and the surface will dry much more slowly.”

Biodiversity

Cover crops also increase biodiversity by providing food and habitats for natural pest enemies, as well as attracting pollinators. They also release compounds such as glucosinolates that suppress soil-borne pathogens or pests. Many cover crops can also be used as food for grazing livestock. Additionally, cover crops compete with weeds that would otherwise grow unchecked. Increased seeding rates (1.5 to 2 times normal) ensures the crop canopy closes rapidly, improving weed competitiveness.

Reducing Soil Compaction

The roots of the cover crop improve soil structure by creating passages that allow for increased moisture and aeration. Soil compaction is essentially eliminated when seeding is done with aerial application.

Additional Resources

The speed and efficacy of aerial application are why it is a critical part of agricultural production in the U.S. and why aerial application is part of the solution to tackling climate change. There are four significant ways aerial applications reduce greenhouse gases and improve the climate.

1. Preserving Land

Aerial application plays a key role in maximizing yield on existing farmland and reducing the need to convert more land into cropland. Research conducted by Senarath Dharmasena Ph.D., Assistant Professor with Texas A&M University’s Department of Agricultural Economics, shows the importance of aerial application for higher yield agriculture for major crops in the U.S. His research, presented at the 2020 Ag Aviation Expo in Savannah, Georgia, looked at five crops: corn, wheat, cotton, soybeans and rice.

Dr. Dharmasena calculated the reduction in yield for each crop that would occur if aerial application was not available. Using data from the 2019 NAAA industry survey, it was determined that the aerial application industry is directly responsible for the production of 1.69 billion bushels of corn, 199 million bushels of wheat, 548 million pounds of cotton, 295 million bushels of soybean, and 3.33 billion pounds of rice annually that would be lost every year without the aerial application of pesticides. The total area of cropland needed to replace this lost yield is 27.4 million acres, an area roughly the size of Tennessee. This research covered only five crops, so it does not fully account for the 127 million acres treated by aerial application annually. Therefore, aerial application protects at least 27.4 million acres from being converted into cropland every year.

2. Increasing Pesticide Efficiency

Dr. Dharmasena applied an average yield reduction of 25% when aerial application is replaced by ground application. This is in part due to the precision and efficacy of aerial application, as demonstrated with the yield differences referenced earlier, and greater productivity of aerial applications. Aerial applications can be made in a timelier manner than ground applications because of their ability to spray when the ground is wet and cover more ground in less time than a ground sprayer.

The productivity of aerial applications also plays a crucial role in managing pesticide resistance. All pesticides have a window when they are most effective on the targeted pest. Applications made after this window passes dramatically decrease the effectiveness of the pesticide, which can result in reduced yield and additional applications to attempt to control escaped pests. It can also speed up the development of resistance to additional types of pesticides.

To compare the productivity between aerial application and ground application in a row crop agricultural setting, an aerial applicator and ground applicator from Mississippi were asked to provide details about the productivity of their application equipment. The aircraft was an Air Tractor AT-502B with a 60-foot swath width, and the ground rig was a John Deere R4030 with a 90-foot boom. During an average 12-hour day, the aircraft treats 1,800 acres while the ground rig treats 450 acres, meaning aerial application is roughly four times as productive as ground application.

The greater productivity and efficacy of aerial applications result in greater pesticide efficiency. Graham Brookes and Peter Barfoot concluded that greater efficiency with pesticides helps farmers adopt reduced tillage production systems, which Bruner et al. show could reduce an additional 17.7 million metric tons of carbon equivalent annually if 25% of intensive or reduced tillage acres were converted to strip tillage or no-till soil management practices. Such a conversion would be equivalent to removing greenhouse gasses released by 3.8 million cars driven for a year.

3. Enhancing Cover Crops

One of the most promising conservation practices aerial applicators can assist farmers with is cover crops. Cover crops are grasses, legumes, small grains and other low-maintenance crops planted specifically to improve soil health and biodiversity. By sowing the seeds aerially with a preharvest cover crop application, cover crops control erosion, retain and recycle soil nutrients, build organic matter to improve soil health, enhance water quality and moisture availability, and break disease and insect cycles.

Growing cover crops is a way that agricultural production can increase soil carbon sequestration, which involves removing and storing carbon dioxide from the atmosphere. The average emission reduction coefficient (ERC) for cover crops grown in cool temperate moist and warm temperate moist zones reported in Bruner et al.’s study “Combatting Climate Change on US Cropland: Affirming the Technical Capacity of Cover Cropping and No-Till to Sequester Carbon and Reduce Greenhouse Gas Emissions” is 0.495 metric tons of CO2 per acre per year. Data from the 2019 NAAA industry survey shows that aerial applicators seed 3.8 million acres of cover crops annually. This means that aerial applicators are responsible for helping to sequester 1.9 million metric tons of CO2 equivalent annually, which, according to the EPA, would be the equivalent of removing approximately 412,000 cars with carbon-combustion engines from the roads each year.

The Bruner et al. analysis further found that if cover crops were grown on an additional 15% of available U.S. cropland acres, there would be an additional reduction of 11.9 million metric tons of carbon equivalent—or the equivalent of removing from the roads annually approximately 2.6 million cars with carbon-combustion engines. Aerial application will play a key role in increasing the acres of cover crop grown. While there are several methods of seeding cover crops, aerial application is the most effective means of applying cover crops successfully. The best time to apply many cover crops is when the harvestable cash crop is still standing. Aerial application offers the ability to spread the cover crop seed over the existing crop without disrupting the standing crop. This means the cover crop can already be established when the cash crop is harvested. Aerial application can also be used when the soil is wet and can seed many acres quickly. The Soil Health Partnership recognizes that aerial application’s ability to apply seed earlier in the year results in better growth and overwintering of cover crops. Michigan State University Extension also recognizes that aerial application is a good option for applying cover crops.

4. Precision Agriculture

Precision agriculture improves the accuracy and efficiency of all facets of agriculture and is heavily utilized in aerial applications. Precision agriculture technologies aerial applicators use include Global Positioning System (GPS) units, more effective nozzles and boom-lowering systems that position nozzles in less-disturbed air for improved application accuracy. According to NAAA’s most recent aerial application survey in 2019, 99.9% of aerial applicators use a high-tech navigational GPS to ensure a targeted application and also aid to prevent overspray, drift and unintended exposure to people or the environment.

Innovative technology exists that combines GPS, GIS based prescription maps and the variable rate flow controller to allow the product to be applied in varying dosages according to what the condition needs are in the field and targeting the material to be delivered only where it’s needed. This enables less product to be used, covering more acres, resulting in less potential for drift and less fuel used, both of which benefit the environment. Aerial applicators make liquid and dry variable rate applications to ensure pesticides, nutrients and seeds are applied at the precise rate needed in each section of a field.

Because it is the responsibility of the agricultural aircraft operator to be aware of sensitive areas when applying products, the majority of ag aircraft are also equipped with smokers. Smokers enable pilots to safely inject a small amount of vegetable oil into the aircraft exhaust system that results in smoke being created, allowing the pilot to determine, as the smoke moves in the atmosphere, the wind direction and an estimate of wind speed.

Another precision application system being used by ag aviators to ensure more targeted and efficient applications of crop protection products is the Aircraft Integrated Meteorological Measurement System, also known as AIMMS. AIMMS adds an additional layer to the precision ag system by incorporating a real-time onboard wind speed and direction measurement system. The atmospheric data collected by AIMMS is then synchronized with the GPS unit and GIS Software. This enables the variable rate flow controller to apply the product, factoring outside wind speed and direction, resulting in an even more precise application. Additional information on the precision application technologies used by aerial applicators can be found in the Fall 2018 issue of Agricultural Aviation.

Growing List of Studies Touts Aerial Application’s Yield Benefits

More and more evidence continues to be collected about the benefits of aerial application compared with other forms of application. Aerial application’s speed is obviously one attraction, which helps in quickly eradicating a crop threat. Aerial’s ability to treat in conditions and locales where other forms of application can’t is another one of its benefits. The ability to treat in multiple conditions also results in better timing, enabling the farmer to treat the crop at its most efficacious point regardless of field conditions. When excessive rain hits, farmers rely on aerial fertilizer and other crop input applications because it’s the only method available to access their fields.

With all those benefits stated, the research that continues to accumulate most readily on aerial’s benefits focuses on how it prevents runoff of essential topsoil and prevents soil compaction which can result in a less hospitable growing environment for a crop and reduce yields, nutrients and moisture. Higher yields are also due to aircraft treating above the crop canopy and not in the crop canopy where ground rigs can trample a portion of the crop, again ultimately reducing its yields. These studies are not only good news for aerial applicators to share with their current or prospective farmer-customers but also good news to help in developing a more friendly policy environment for aerial application. Industry sage Bill Lavender recently forecast that the agricultural aviation industry’s future will always be in demand because of the pressure to produce higher and higher yields. Lavender wrote that “environmentalists work in our favor when they protect forests and wetlands from cultivation … [because] we have to produce more food on less land. The best way to do that is incorporating ag aircraft in the plan for higher yields.”

A handful of food companies, including Cargill, Coca-Cola, PepsiCo and Wal-Mart, made commitments to reduce their carbon footprints as part of a White House initiative to get the private sector to do more to fight climate change. As part of those commitments, these companies plan to reduce greenhouse gas emissions by 5 percent and improve water and energy efficiency by the same amount over the next five years. High-yield agriculture using aerial application to maximize those yields will be a key component for these food producers and suppliers to meet their commitments.

Below is a summary of studies underscoring aerial application’s crop yield producing advantages and links to the studies themselves or webpages with additional details about the studies:

A Purdue University study shows ground applicator rigs damage approximately 1.5 to 5 percent of soybean crops. The study may be found here.

An analysis by Russ Gasper with the Nebraska Department of Aeronautics calculates a significant corn yield boost using ag aircraft. Using the aforementioned Purdue University study, Gasper used the same assumptions with corn damage in Nebraska and found that it costs the state 6,366,000 bushels of corn or approximately $34 million in economic activity annually. Gasper’s paper can be found here.

A joint 2008 American Society of Agricultural and Biological Engineers study conducted by Bob Wolf, PhD, of Kansas State University, and Scott Bretthauer, PhD, of the University of Illinois shows an 18.6 bushel-per-acre yield increase in corn treated with fungicide compared with untreated corn. The study may be found here.

AgriNews, a Midwestern publication covering agri-business topics, ran a story about Illinois-based Schertz Aerial Spraying conducting research on aerial fertilizer applications. The results showed that applying ammonium nitrate during a soybean’s R2 full flowering stage increased soybean yields by 10 to 15 bushels over the 70-bushel base yield. Scott Schertz, the company’s owner, stated in the article that ag aircraft are well suited for late-timed fertilizer applications because they can deliver the product to the crop when it needs it the most without disrupting the crop or the field. The AgriNews article may be found here.

Another strong piece of academic evidence favoring aerial application stems from the University of Minnesota Extension’s website that has collected an assortment of research indicating soil compaction from ground rigs can negatively affect crop yields. The conclusions made are that a moderate amount of compaction is desirable at seed time; however, too much under dry conditions can be detrimental to yield; under wet conditions any amount of compaction can decrease yields, as it results in nitrogen loss, reduced potassium availability and inhibition of root respiration due to reduced soil aeration. In addition, the research shows that excessive compaction decreases water infiltration and storage, decreases root growth, and reduces the soil volume explored by the roots all of which, again, can reduce crop yields. The University of Minnesota soil compaction information may be found by here.

Aerial Application operators across the country have partnered with the Ag Container Recycling Council (ACRC), a not-for-profit organization that safely collects and recycles empty pesticide containers. These containers, made of high-density polyethylene (HDPE), are collected at 1,500 approved collection points around the U.S. where professional contractors process the HDPE and sell it for re-use. End-uses of this recycled HDPE is used for the following:

- Agriculture drain pipe

- Highway sign posts

- Highway and agricultural fence posts

- Underground utility conduit

- Wire and cable spool (reel) flanges

- Agrochemical composite IBC platforms

- Industrial pallets for ag chemical and seed packaging

- Rebar chairs

- Landscape edging

- Nursery Pots

In September 2019, the ACRC announced their contractors collected the 200 millionth pound of HDPE since the program was started in 1992. The first 100-million-pound milestone was accomplished in 2008 after 16 years of collection. With this second 100-million-pound milestone accomplished in only 11 years, the next 100-million-pound milestone is expected to occur in seven years based on the current collection rate.

Aerial applicators treat 28% of our nation’s commercial cropland according to NAAA’s 2019 Aerial Application Industry Survey. This does not include pasture and rangeland, forestry, aquatic, public health, right away and other vegetative management applications done by air. Using this percentage of 28%, aerial applicators are responsible for helping to recycle 56 million pounds of HDPE in the past decade and a half. Recycling that much plastic is an energy-savings equivalent to saving 43,019,361 gallons of gasoline. This is also equivalent to the energy consumption of 57,518 average American houses for a year.

If you would like more information about recycling pesticide containers visit the Ag Container Recycling Council at http://www.acrecycle.org, or information@acrecycle.org or call at (877) 952-2272.

Aerial application of crop protection products is an essential tool for American farmers.

FAQs

Aerial application is often the safest, fastest and most efficient, and most economical way to get the job done. Aircraft help in treating wet fields and spraying when crop canopies (i.e., orchards) are too thick for ground rigs. When pests or disease threaten a crop, time is critical. An airplane or helicopter can accomplish more in one hour than ground equipment can in one day. This means less fuel used, less air pollution and no soil compaction. Aircraft are necessary to low or medium-tillage farming systems, which can reduce soil erosion by as much as 90%. Aerial application provides food, fiber and bioenergy for the world’s growing population and protects our natural resources.

The world population continues to grow at a fast pace. Today there are 6.6 billion people, but it is estimated there will be more than 9 billion people by the year 2050. World food needs will double, but land area suitable for farming is not increasing. To produce future food, fiber and bioenergy and leave room for wildlife we must increase production on the land we are now using. High-yield agriculture benefits the environment by producing maximum crop yields from a small amount of land.

Like the human body, all plants need proper nutrition and protection from diseases and pests to attain maximum growth. This is true regardless of the farming system.

“Pesticides are a key part of modern agriculture, contributing to the dramatic increases in crop yields achieved in recent decades. Pesticides are used in both organic and conventional farming. Through the use of pesticides, farmers are able to produce crops profitably in otherwise unsuitable locations, extend growing seasons, maintain product quality and extend shelf life. In fact, it’s better pesticide science that has allowed North America to triple its food production while maintaining the same amount of forest cover as existed a century ago,” said Dr. Patrick Moore, Greenpeace Co-Founder and Chairman and Chief Scientist of Greenspirit Strategies.

All crop protection products must meet tough safety standards. Only one in 20,000 chemicals actually survives the 8–10 year process of development, testing, and registration by the U.S. Environmental Protection Agency (EPA). Costs to test a pesticide’s safety can range in price from $160 to $200 million.

Nearly 900 scientists and program officials from the EPA make sure that products are properly registered to comply with federal law. Once on the market, they are monitored by the EPA, the Food and Drug Administration (FDA) and state pesticide enforcement agencies. This stringent regulatory system ensures the safety of our food, the safety of the products to the environment, to water and to the farm workers that mix, load and apply the products.

The American Cancer Society states:

“Many kinds of pesticides are widely used in agriculture in the production of our food supply. People who eat more fruits and vegetables, which may contain trace amounts of pesticides, generally have lower cancer risks than people who eat fewer fruits and vegetables. Pesticides play a valuable role in sustaining our food supply. When properly controlled, the minimal risks pesticides pose are greatly overshadowed by the health benefits of a diverse diet rich in foods from plant sources.”

Aerial application helps make it possible for us to have these fresh fruits and vegetables year round. Pesticide use has resulted in increased availability and a variety of low cost, fresh fruits and vegetables year round. This has had significant impact on human health because there is strong evidence that increased consumption of fresh fruits and vegetables is associated with a reduced risk of chronic disease, including many cancers. Crop protection products also play a role in enhancing the safety of the food supply by reducing levels of natural toxins, such as mycotoxins and reducing the potential for contamination of fresh produce by food borne human pathogens.

Yes, organic farmers employ the services of aerial applicators. Because organic spraying is preventative, aerial applicators spray organic crops with approved organic pesticides almost daily to prevent any infestations from starting. Like conventional farming, timing is crucial and when spraying needs to be done for organic fields, it needs to be done quickly. According to the National Organic Program (NOP), which is overseen by the USDA, organic crop pests, weeds and diseases must be controlled primarily through management practices including physical, mechanical and biological controls. Also according to the National Organic Program, when these practices are not sufficient, a biological, botanical or synthetic substance approved for use on the ‘National List’ may be used. Substances that may be used include horticulture oils, sulfur, copper, pyrethrum, rotenone, Bt and spinosad.

According to former USDA Secretary Dan Glickman:

“The organic label is a marketing tool. It is not a statement about food safety. Nor is organic a value judgment about nutrition or quality. Organic is about how it is produced. Just because something is labeled as organic does not mean it is superior, safer or healthier than conventional food. All foods in this country must meet the same high standards of safety regardless of their classification. For nutrition information, look at the nutrition label. And as for quality, that is a matter of personal preference.”

Because “crop dusting” doesn’t begin to describe the way the industry has developed since it began in 1921. For one thing, most applications today are in liquid form, so the word “dusting” doesn’t say enough. For another, today’s aerial applicators do much more than their predecessors did. The best term for them might be “Crop Doctors,” because they must administer the proper treatment, at the correct dosage and time, to keep the plants healthy.

In addition to controlling insects, weeds, and diseases that threaten crops, they perform many other vital jobs. Aerial applicators “plant” seed from the air into flooded rice fields; spread rye grass seed in cornfields prior to harvest to prevent soil erosion; and they fertilize and add nutrients to soil for healthy crops and forests. Aircraft are also used to help clean up oil spills in the ocean and harbors, feed fish, protect human health by controlling flies and mosquitoes that carry harmful diseases. They protect our natural resources by reducing disease and pest infestations in forests and other areas inaccessible by ground equipment. Aerial application aircraft are also an important tool in fighting fires and preventing fires from spreading.

Today’s operators fly both helicopters and fixed-wing aircraft especially designed for this purpose. These aircraft range in price from $100,000 to $1,400,000. They are ruggedly built to handle 30 to 100 take-offs and landings every day from rough landing strips, and they offer protection and good visibility for the pilot. Today’s aircraft utilize sophisticated precision application equipment such as GPS (Global Positioning Systems), GIS (geographical information systems), flow controls, real time meteorological systems and precisely calibrated spray equipment to make sure the pilot is accurate in applying the correct amount of product onto the crop. On the ground, the airplanes are loaded by workers uniformed in protective clothing using closed mixing and loading containment systems to ensure safety to the environment and the worker.

Aerial applicators are highly-trained professionals who have made a very large investment in their business. Like all Americans, they are concerned with human health, the environment, security and performing their job in a responsible manner. More than 90% own their own business and operate their aircraft. The average aerial applicator has over 20 years experience in the industry, but a number of new agricultural pilots enter the aerial application industry each year. Many of these operations are family businesses with family members responsible for aspects such as product mixing, aircraft maintenance, refueling, bookkeeping, work scheduling, weather monitoring, field scouting, and customer relations.

The professionals who apply crop protection products operate under the watchful eye of federal and state agencies. These agencies have at the top of their lists public health and worker safety and environmental protection. They include the Environmental Protection Agency (EPA), Department of Homeland Security (DHS), Federal Aviation Administration (FAA), Department of Transportation (DOT) and individual State Departments of Agriculture, Ecology and Environment.

Regulatory personnel inspect operations and require strict and specific documentation of each field sprayed. These same agencies continually monitor environmental and public health to assure that we continue to have the safest, least expensive, and most abundant food supply in the world.

Although the aerial application industry had security measures in place before the tragic events of 9/11/01, the National Agricultural Aviation Association and its membership have aggressively promoted enhanced security procedures developed in the wake of 9/11/01.

A few security measures pertaining to the ag aviation industry include: comprehensive background checks by local, state and federal agencies; the development of site security operation plans in compliance with the DOT; and installation of hidden security switches to prevent unauthorized startup of the aircraft.

The aerial application industry continues to work closely with local, state and federal officials and we are committed to doing everything we can to help government officials make sure that public safety concerns do not deprive the American people of the benefits they receive from agricultural aviation.

From the beginning, the aerial application industry has strived to improve equipment and techniques to provide for accurate and effective delivery of products to crops. In the 1960s the National Agricultural Aviation Association (NAAA) was established to foster industry development to the highest standards. NAAA developed the Professional Aerial Applicators Support System (PAASS) to educate pilots about safety, security and drift mitigation. PAASS is committed to reaching every aerial applicator in the U.S. with the latest information regarding these issues. In addition, the NAAA works with the federal government to invest in researching, developing and testing aerial application technologies to strengthen the safe application of crop protection products by air.

Being an ag pilot is one of the most exciting jobs in aviation. It requires tremendous skill and precision. If you enjoy aviation video games or enjoy the outdoors and rural living, you may be a perfect addition to the agricultural aviation industry. It’s not an easy job, it takes a significant amount of training and the hours during the busy flying season can be long. But it is a fulfilling job. Ag pilots provide an essential service to farmers, foresters and the public at large. Ag pilots love their ability to soar through the skies in beautiful and serene farm country. In many areas across the country it is also a seasonal job, which can allow for other leisure or professional opportunities during the off season. Visit our Careers Section to read about careers and mentoring in the aerial application industry.

From the beginning, the aerial application industry has strived to improve equipment and techniques to provide for accurate and effective delivery of products to crops. In the 1960s the National Agricultural Aviation Association (NAAA) was established to foster industry development to the highest standards. NAAA developed the Professional Aerial Applicators Support System (PAASS) to educate pilots about safety, security and drift mitigation. PAASS is committed to reaching every aerial applicator in the U.S. with the latest information regarding these issues. In addition, the NAAA works with the federal government to invest in researching, developing and testing aerial application technologies to strengthen the safe application of crop protection products by air.